What is a concrete slip test?

Concrete slump test

Proper concrete compatibility is critical to the success of a project. If the concrete is too wet, it may crack, and it will not be easy to pour and work with if it is too dry. But how do you know what the workability or efficiency of concrete is? The best-recommended method is the “concrete slump test”. In this article, we will discuss the slump and its importance in concrete production.

What is a concrete slump?

A concrete slump is a measurement of the efficiency or consistency of the concrete mix. Slump can also be described as the fluidity of the concrete mix. If the slump rate is high, the concrete mix is more fluid and enforceable, and conversely, a low slump means that the mixture has less fluidity and workability. The slump of the concrete mix is determined using the slump test.

Understanding the consistency of concrete mixes is helpful for several reasons. This test allows you to evaluate the performance of the concrete mix before concreting. This test is also necessary to create a product with a more desirable consistency for any construction project. This test is an experimental test that measures the performance of fresh concrete and is very popular because of its simplicity.

Importance of concrete slump test

Freshly mixed concrete, which will soon be poured on-site, must meet specific standards before being used as part of a construction project. A slump test can measure the consistency of concrete to determine how smooth the concrete is. This test detects defects in the mixture and allows the operator to correct the mixture before pouring it in place. By measuring the slump, it is possible to determine the ratio of water to cement, whether the mixture is highly efficient or not!

The main reason for performing slump testing is to ensure the quality and strength of concrete. The more water added to the mixture, the weaker the concrete. If the project’s necessity necessitates the use of higher performance concrete, we must ensure that the concrete still reaches its desired strength. This test is just one of the ways to ensure the quality of concrete that can be easily done in the construction site by the workshop supervisor or contractor.

Principles of Slump Test

The slump test measurement is the measurement of the inverse behaviour of a compacted concrete under gravity. This test determines the flow rate of the concrete (moisture or dryness) and then provides an idea of the operating conditions of the concrete mix.

The following devices are used in the slump test:

The following devices are used in the slump test:

-

Metal mold in the form of an incomplete cone (Slump Cone) with a lower diameter of 20 cm, an upper diameter of 10 cm and a height of 30 cm

-

Tamping Rod with a diameter of 16 cm and a length of 0.6 m

- Steel Ruler

- Base Plate

- Slump Cone Funnel

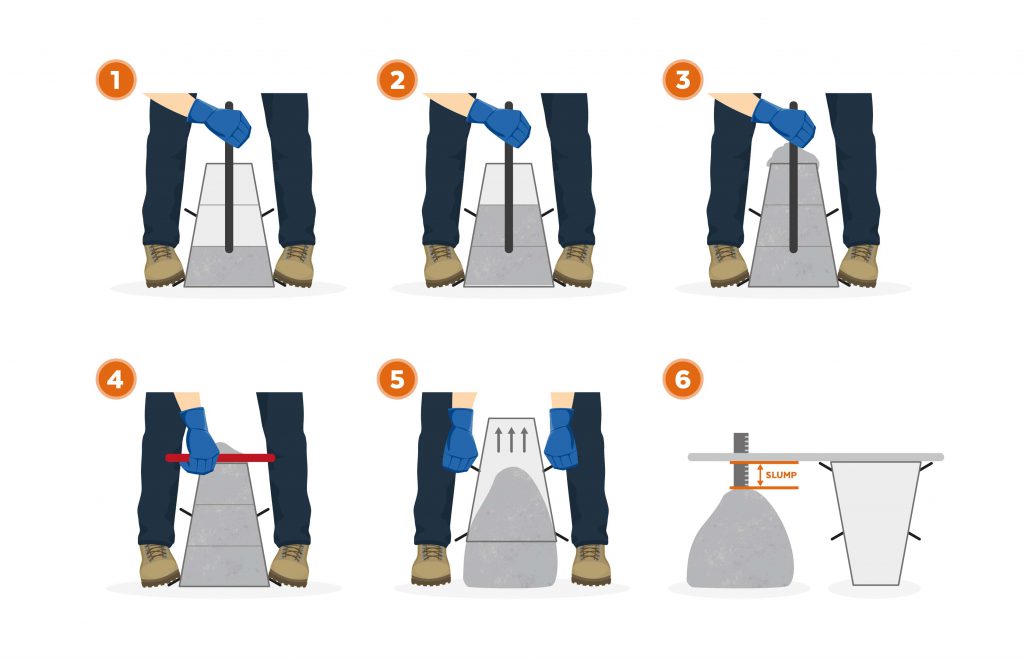

Description of concrete slump test

The steps for performing the slump test are as follows: First, we fill a defective cone known as the “Abrams cone” with fresh concrete. The cone is then removed, and the amount of “drop” of concrete without metal coating is measured. By placing the cone next to it and measuring the difference between the top of the cone and the height of the fallen concrete, one can observe the result and measure the amount of concrete drop. In fact, the rate at which concrete falls is called a slump.

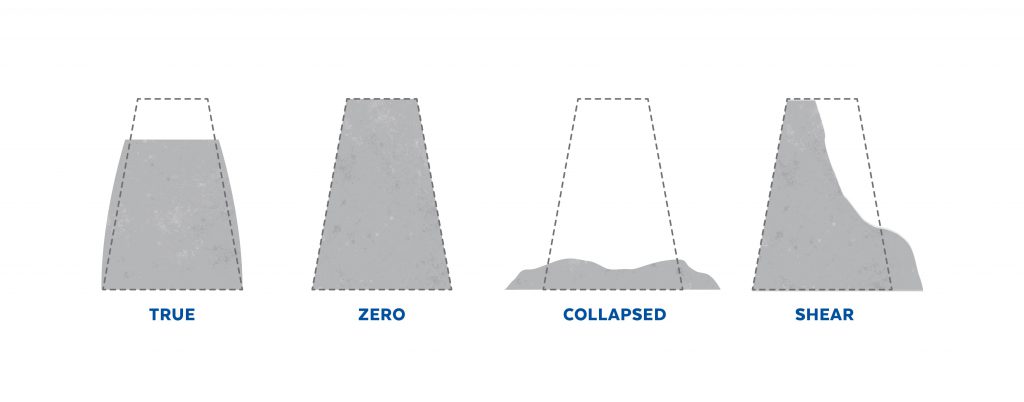

The four results of the concrete slump test are as follows:

- Zero Slump: The mixture is not very dry and workable if the concrete retains its full shape after removing the cone.

- True Slump: This is the amount you are looking for. This means that the concrete has a good consistency. After removing the cone, the concrete will retain much of its shape but will experience some drop.

- Shear Slump: The concrete mix falls dramatically from one side, which means the concrete is very wet and has a high flow rate.

- Collapse Slump: If the shape of the concrete is completely damaged after removing the cone, the mix is very watery and unusable ( high water-cement ratio).

Tips for performing concrete slump test:

-

-

- The base of the cone should be on a flat surface and a funnel placed in the mouth of the slip container to fill the concrete in three layers.

- Each layer is beaten 25 times with a standard steel rod 16 mm in diameter to compact the concrete. Tapping should be done in a circle.

- Once the formwork is completely filled with concrete, the concrete surface should be level to the opening.

- The formwork must be firmly in place during the work so that it cannot move due to the pouring of concrete, and this can be done by attaching the handles to the base.

- Immediately after the concrete has been filled and levelled, the cone is gently and carefully lifted vertically to measure the amount of concrete drop.

-

Note: For a quick test, a new device called the K-Slump Tester has been developed. This device can measure the amount of slump in one minute.

Factors influencing concrete slump test

-

-

- Water- cement ratio

- Quality, shape, moisture content, texture and grading of coarse (sand) and fine (sand) aggregates

- Use of lubricants, super-lubricant additives and the order of their mixing

- The void ratio in concrete

- Test time after concrete mixing

-

Applications of slump test

-

-

-

The slump test is used for the effect of lubricants in the concrete mix.

- This test is useful as a test of day-to-day or hour-by-hour changes in concrete mix ingredients. An increase in a slump may mean, for example, that the moisture content of the aggregate has increased unexpectedly.

- A slump can be used to change the grading of concrete aggregates.

- Too much or too low slump gives an immediate warning to the mixer operator to remedy the situation immediately.

- This application of the slump test and its simplicity are responsible for its widespread use.

-

-

The following table describes the allowable slump of concrete according to issue 55:

| Row | Concrete member | Slump | |

| Min | Max | ||

| 1 | Reinforced concrete foundations | 25 | 75 |

| 2 | Plain concrete foundations and structure walls | 25 | 75 |

| 3 | Reinforced concrete beams and walls | 25 | 100 |

| 4 | Column | 25 | 100 |

| 5 | Concrete slabs and concrete sidewalks | 25 | 75 |

| 6 | Bulk concrete | 25 | 50 |

Note: If the vibration is done manually, 25 mm can be added to the maximum amount of slump.

Concrete slump class

In addition to the observation, the difference between the height of the cone and the height of the slumped concrete must also be measured. In this way, the slump can be classified according to European standards (BS 8500) as follows:

| class | rate (mm) | Slip the target(mm) |

| S1 | 10 until 40 | 20 |

| S2 | 50 until 90 | 70 |

| S3 | 100 until150 | 130 |

| S4 | 160 until210 | 180 |

| S5 | more than 210 | 220 |

Each of these five classes specifies the amount of target slump and is used for different applications depending on the consistency of each class. In some cases, if a specific class of slump is not obtained for the application you are using, it may need to be modified. In any case, it is best to consult an engineer or a qualified concrete supplier.

Slump test standards

-

-

- American Standard: In the United States, this test is known as the “Standard Test Method for Hydraulic Concrete-Cement Slump” and carries the code ASTM C143 OR (AASTO T119).

- England and Europe: An older standard for Britain and the countries of early Europe (BS 1881–102). But now, they are using new standards (BS EN 12350-2).

Indian standard:

The Indian standard is IS 1199-1959.

-

Conclusion :

This test demonstrates the performance of the concrete and its ease of flow, as well as an unsuitable mix category. A fall test can help make each one more uniform when working on a large project with multiple concretes. Therefore, knowing your concrete compaction and its category is essential to preparing the concrete mix for the job.

sources: