What is a concrete slab?

What is a concrete slab?

A slab is a concrete structural element that is used to construct horizontal flat surfaces, such as floors and roof decks. Typically a few centimeters thick, a concrete slab is supported by beams, columns, and walls. The slab can be constructed on-site with ready-mixed concrete and pumped by a mixer truck, but what is a concrete slab, and what components does it comprise? Stay with us for the answer.

Definition of concrete slab

A concrete slab is a flat element comprised of reinforced concrete. Due to the slab’s extremely low height-to-length and width-to-width ratio, it is called a flat member. The concrete slab can function as both a roof and a foundation. For instance, a broad foundation (general radius) is a reinforced concrete slab.

In the slab roof, one-way slabs and two-way slabs are distinguished. The length-to-width ratio of the span is more than two, and the first mode is supported on both sides. The ratio of span length to span width is less than two in the second mode, which is supported on all four sides. These slabs are utilized in both concrete and metal buildings.

Consideration is given to the building type, architectural design, aesthetic characteristics, and span length while designing and constructing concrete slabs. One-way beam slabs, flat slabs, flat plates, waffle slabs, hollow-core slabs, prefabricated slabs, slabs on ground, resistant slabs, and composite slabs are subcategories of concrete slabs.

The following describes the general performance of a concrete slab:

- To make a surface smooth

- As thermal, acoustic, and fire insulation

- Developing protections against environmental hazards

- Dead and live load transfer to perimeter beams

- Adding additional floors to a building

Types of concrete slabs

Below, according to the place of use, we have divided the slabs into the following types:

Foundation slab

The reinforced concrete foundation slab functions as a wide (general radius) foundation. For this sort of slab, it is essential to design the slab around the soil, as some soils, such as clay, is insufficient to support the structure. This causes the slab to fracture and deform, which may eventually cause the structure to collapse.

The massive foundation concreting procedure begins after reaching the solid ground (through excavation). Concrete curing must be done correctly in order to achieve the desired strength. As these foundation slabs are absolutely put in place, it will be challenging to improve the curing process by controlling the environment. Water-absorbing polymers and bags are commonly used for this purpose.

Attention: If properly engineered, the use of unreinforced slabs is allowed, but in buildings located in seismic zones or on unstable soil, the foundation slab must be reinforced.

Roof slab

The roof slab is a flat feature of steel and concrete structures, as its name suggests. This slab is subdivided into the following categories:

Flat Slab

The load is transferred directly from the flat slab to the columns without being transferred to the surrounding beams. When the space between the columns is short and the incoming loads are small, this form of the slab is utilized. Among the several varieties of flat slabs is the flat slab supported by column heads (Waffle Slabs), which are used to neutralize negative anchors in the slab-column interface.

Corrugated Slab

Corrugated Slabs are created by pouring concrete over corrugated (galvanized) metal sheets. This roofing material is also known as Corrugated Slab. These steel sheets strengthen the slab and serve as a mold for the concrete. Studs link the steel sheet to the sub-beams to initiate the concreting process.

Ribbed Slab

The ribbed slab is identical to the joist block roof, which exhibits resistance in one direction by directing the roof’s dead and live loads to one side, length, or width. This kind of concrete slab is typically used for concrete structures and is created using metal beams and blocks (these days, Styrofoam is used instead).

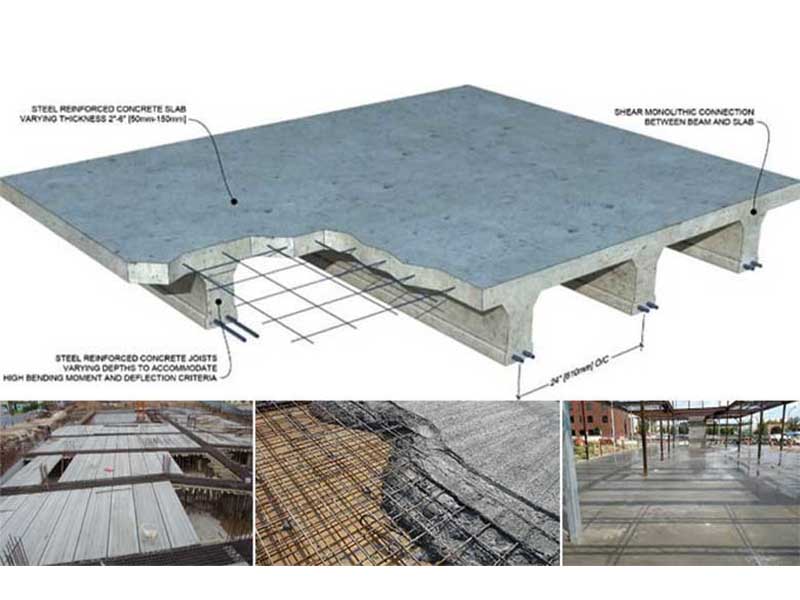

Waffle Slab

Using a matrix of depressed sections beneath the slab, a waffle slab transfers the incoming load in two directions. Waffle slabs are typically thicker and hence heavier than ribbed slabs of comparable strength. This slab enhances the roof’s strength in two directions, which is crucial for seismic resistance and the roof’s diaphragm.

Design of concrete slab roof

The design of a concrete slab depends on how the load is transferred. Therefore, the design can be divided into the two categories below:

One-way slab

A one-way slab transfers load in only one direction (length or width) to the adjacent beams. Corrugated and ribbed slabs are types of one-way slabs. The design of a reinforced one-way slab may be superior to that of an unreinforced two-way slab. The one-way slab span’s length ratio to its width is larger than two.

Determining reinforcement requirements for a one-way slab can be laborious and time-consuming, and the optimal design cannot be determined with absolute certainty. Even minor project modifications necessitate a recalculation of slab reinforcements.

While developing a one-way slab construction, numerous considerations must be made. These elements include:

- Load calculations (dead load and live load)

- Bending moment calculation

- Acceptable flexibility and deflection depth

- Type and distribution of reinforcing steel in the tensile portion of the structure

Two-way slab

The surrounding beams share the load from the two-way slab. The ratio of the two-way slab’s span length to span width is less than two. This slab may be utilized because of heavy loads, resistance to vibration (earthquake), or other regulatory considerations. In the design calculations for this slab, both orientations must be addressed.

This slab is also suitable for wider spans. The design theory for this is predicated on the notion that loads are lazy and prefer to move along the shortest path with the least amount of effort. Each direction’s weight is carried by all four perimeter beams and transferred to the columns.

Thickness of concrete slab

The thickness of the concrete slab is determined by the structural requirements but is often quantified by the instantaneous and long-term roof deflection. Some standards must be met for solid slabs that are not connected to separators (blades) or other architectural elements and may be harmed by high deflection. In these instances, the overall thickness of the slab (h) must not be less than the values stated in the table below, which are established for conventional concrete and steel with a yield stress of fy=420 MPa:

|

Support conditions |

Minimum Height |

| Simply supported | L/20 |

| One end continuous | L/24 |

| Both ends continuous | L/28 |

| Both ends continuous | L/10 |

L: Length of the span

Procedure for constructing a concrete slab

A structure is composed of several structural connecting parts, including walls, beams, columns, foundations, slabs, etc. Of these, the slab is quite important. It assists other building components in resisting various loads.

The steps involved in producing concrete slabs are:

Metal template installation

The mold should be constructed to bear construction loads, such as the weight of workers, operators, and equipment, as well as the pressure of fresh concrete. The mold must be correctly positioned and fitted. The joints should be sufficiently secured with the clamps so that concrete residue does not escape. The molds should also be greased and cleaned so they may be easily removed from the concrete when opened.

An investigation of mold should be conducted during and after the placement of a concrete slab in order to identify odd deviations and other potential failure signs. Failing to thoroughly inspect the location to ensure the molds are correctly executed can have serious impacts. The two most significant consequences of not correctly applying the molds are the waste of concrete and the high expense of purchasing ready-made concrete.

Roof reinforcement

The roof reinforcing bars are depicted on building plans. These maps contain length, score, bend, and number information. Following the completion of the reinforcing, the bars must be appropriately covered.

This concrete coating is designed to withstand severe weather conditions. The wires serve to secure the primary reinforcement to the secondary. Failure to effectively perform the reinforcement in the area could result in the collapse of the structure when subjected to large forces, such as earthquakes.

.

Slab Concreting Work Procedure

Pouring concrete quickly into the molds will avoid separation and stiffness. Using ready-mixed concrete and a mixer truck, the concrete slab is transported to the construction site and poured by the concrete pump. At this stage, the supervising engineer must control the concrete appropriately.

Fresh concrete should also be sufficiently compacted to be poured into the molds, around the reinforcement, and into each point. The final surface of the concrete is then flattened by vibrating the concrete. Afterward, the molds are opened to begin the concrete curing process.

Mold removal and curing concrete

After completing the concreting process, the project crew must be prepared for curing. Spraying or using bags and plastic to preserve moisture can protect concrete slabs from dampness. It is advised that the molds be removed after 14 days, although the precise number of days will depend on weather circumstances, local regulations, and the opinion of the supervising engineer.

Conclusion

Several parts of a building are connected to one another through various structural elements, such as walls, beams, columns, foundations, slabs, and more. The concrete slab is a member with a very low height-to-length ratio. The slab is utilized in the construction of massive foundations and roofs. One-way and two-way roof slabs are among the most widely used slab design variants. Currently, concrete slabs are used as a structural element in concrete and metal constructions.